During routine inspections, Changsha Drainage Management Company found blocked pipelines where downstream pipe invert was higher than upstream, causing elevated upstream water levels. Urgent assessment of upstream pipe conditions was needed. Since neither the naked eye nor conventional cameras could provide effective imagery, a technology capable of precise detection under flooded and murky conditions was required to ensure the safety and efficiency of the city’s drainage system.

Project Challenges

Long-term high-water levels with turbid conditions

High risk and unsafety with manual inspection

Conventional video inspection unable to penetrate water for clear images

Tight timelines minimizing road occupation

Solution

Use the Sonar View SVF-1 high-resolution sonar connection detection system:

Designed specifically for flooded/murky operations

High-resolution sonar imaging with complete structural detail

Real-time image transmission and recording for immediate on-site analysis

No need for personnel to enter the manhole,ensuring operational safety

Procedure

Install the Sonar View SVF-1 on the manhole inspection platform

Activate sonar scanning mode to scan the manhole walls

Collect and record sonar images and related data

Analyze in real time to identify blockages, flow conditions, and manhole orientation

Inspection Results

Analysis of the pipe diameter, length, and silt thickness for three manholes and their upstream/downstream pipes yielded the following conclusions:

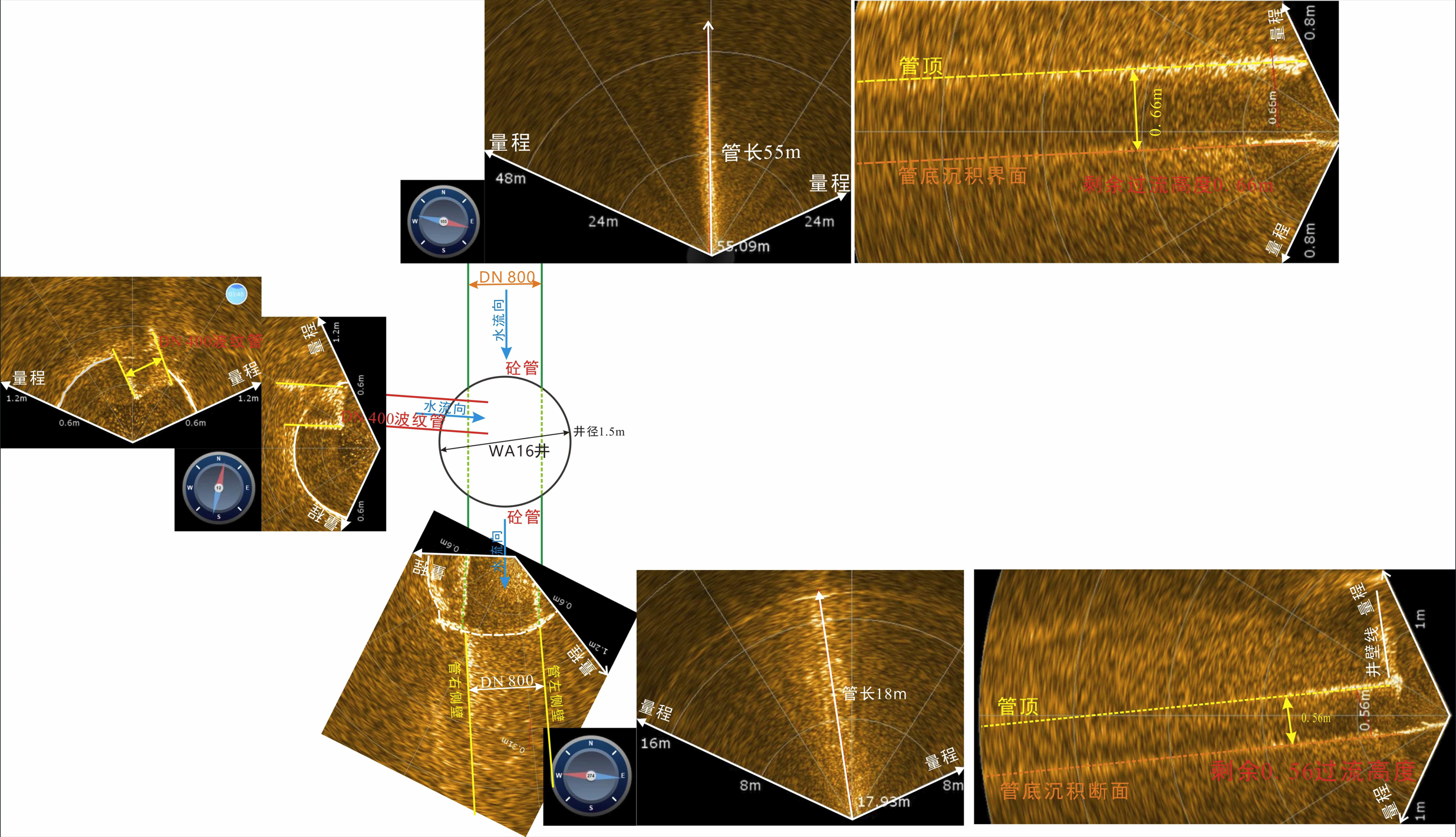

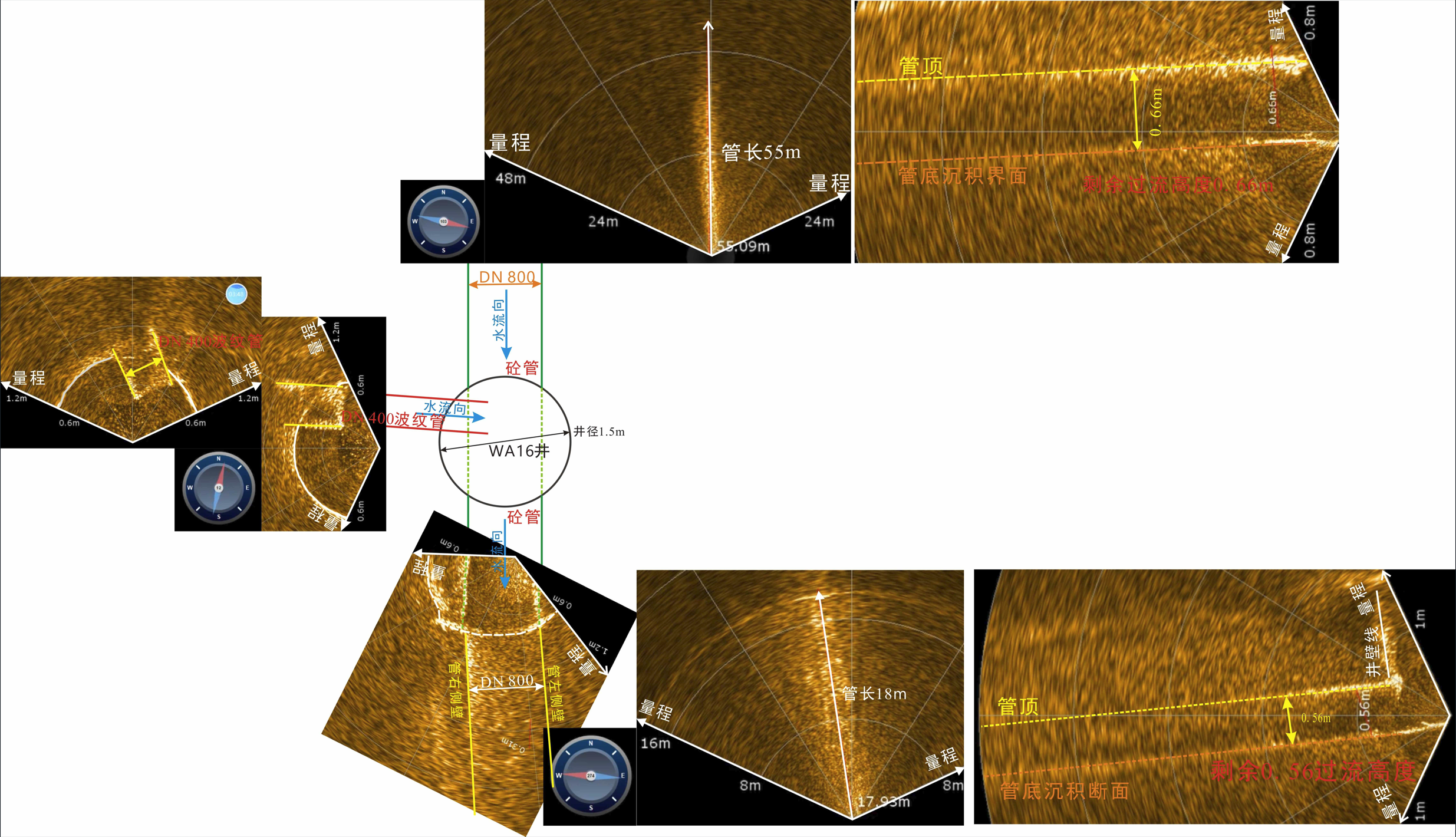

WA16 (1.5 m diameter circular manhole)

East-side upstream main pipe: Concrete pipe, azimuth 103°, length 55m, remaining 0.66m flow clearance at the pipe mouth , silt thickness 0.14m

West-side downstream main pipe: Concrete pipe, azimuth 274°, length 18m, remaining 0.56m flow clearance at the pipe mouth, silt thickness 0.24m

North-side branch pipe: DN400 corrugated pipe, azimuth 12°, sewer pipe for construction site

See diagram for connection and inspection details inside the manhole

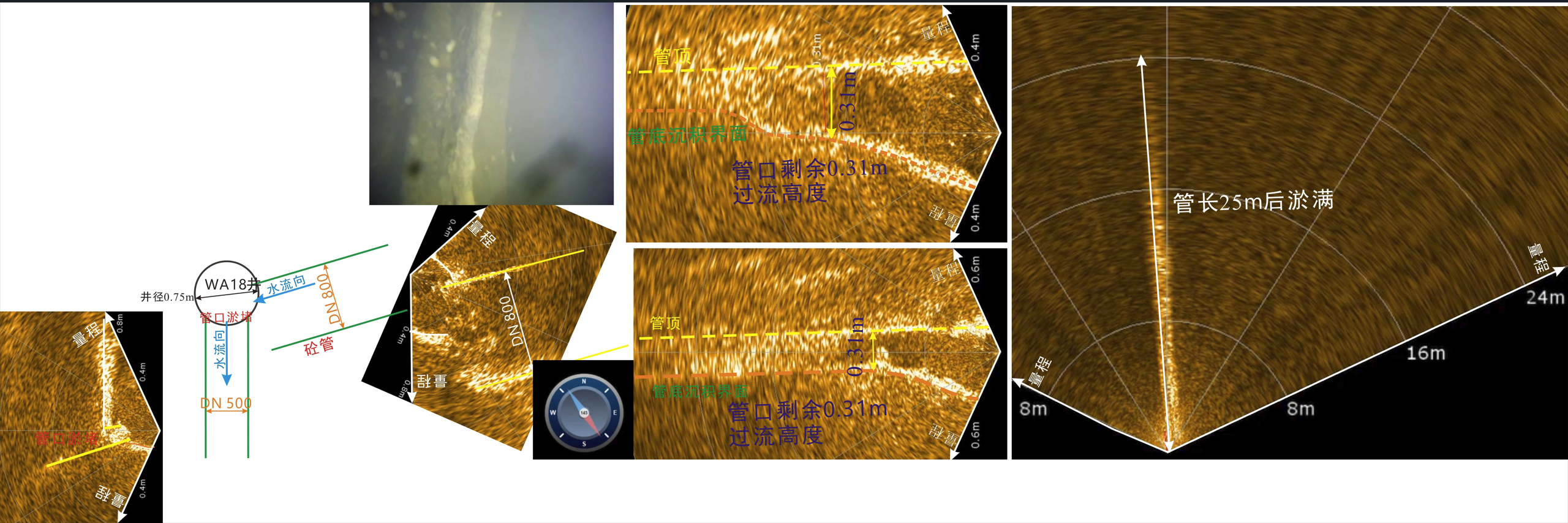

WA18 (0.75 m diameter circular manhole)

Southeast-side upstream main pipe: Concrete pipe, azimuth 143°, fully silted at 25m upstream;remaining 0.31m flow clearance at 1m entry, silt thickness 0.49m, pipe mouth eccentrically and diagonally inserted into the manhole chamber

West-side downstream main pipe: Pipe mouth blocked by silt inside the manhole, only top edge visible (pipe diameter confirmed via downstream WD7088)

See diagram for connection and inspection details inside the manhole

WD7088 (1.7 m diameter circular four-way junction)

East-side upstream pipe: DN500 concrete pipe from WA18, azimuth 76°, pipe mouth blocked by stones; remaining 0.26m flow clearance at 0.5m entry , debris thickness 0.54m

West-side upstream pipe: DN400 concrete branch pipe, azimuth 242°

North–south main pipes (upstream & downstream): DN800 corrugated pipes;upstream azimuth 334°, downstream azimuth 201°, length 48m, remaining 0.63m flow clearance, silt thickness 0.17m; disjoint detected at 20m

See diagram for connection and inspection details inside the manhole

Core Value:

Accurately displays water level, silt thickness,and structural defects for each pipe

Directly identifies blockages and displaced joints

Data can directly support pipeline cleaning,repair, and maintenance decisions