The LBC 01 three-dimensional high-definition intelligent drilling television imaging instrument is an advanced device used for real-time monitoring and recording of the geological structure during drilling. Equipped with high-definition cameras and advanced image processing technology, it can clearly display important information such as geological structures, rock layer changes, and underground pipelines.

The device has a wide range of applications, including but not limited to: inspecting the quality of concrete pouring and grouting to ensure engineering quality; monitoring and detecting geological disasters, providing early warnings and taking corresponding measures; guiding the installation and burial of underground instruments and equipment to ensure their normal operation; inspecting and detecting underground pipelines, and conducting advanced detection for tunnel excavation to provide accurate data for engineering construction; delineating rock types, identifying geological structures, and determining weak mud layers to provide important references for geological exploration and engineering design; detecting geological anomalies such as faults, fractures, and fractured zones to assess geological risks; observing the activity of underground water and assisting in geological mechanics experiments to improve geological research efficiency; conducting exploration and detection of underground resources such as coal mines and oil wells to help optimize resource development and management.

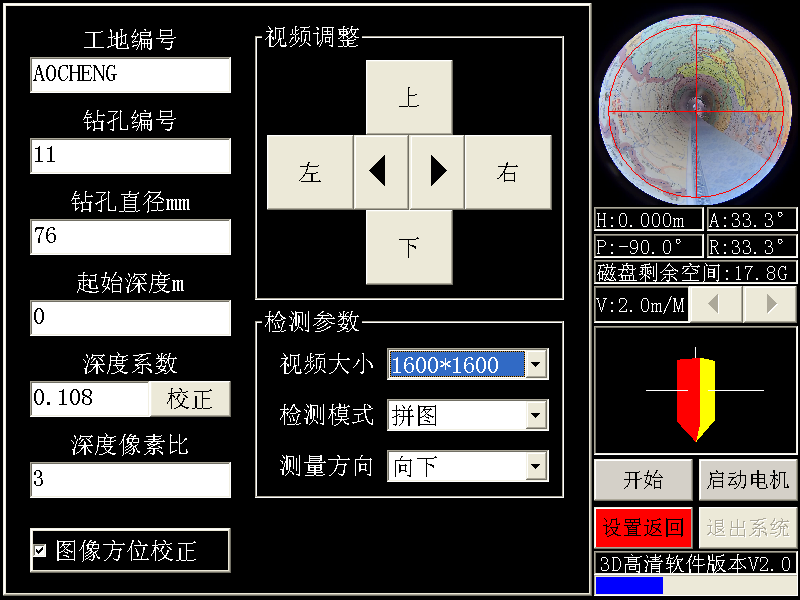

Control software interface

Parameter setting interface

Advantages

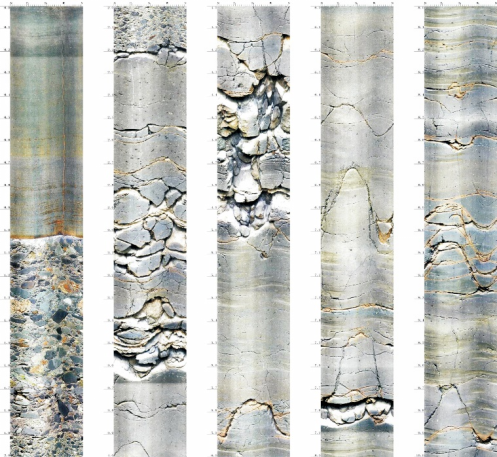

360° Panoramic Imaging

Utilizes a 360° panoramic high-definition ultra-low distortion camera, with the front end of the probe featuring an open-topped toughened glass dome cover, enabling 360° all-round imaging of the drilling wall.

Ultra-High Definition + True Color

Equipped with a standard 5 million pixel high-definition lens, with digitally rendered images displaying true-to-life colors, providing 1:1 imaging with no mosaic when zoomed in, and achieving a crack resolution of up to 0.1mm.

Integrated Imaging + Video Recording

Utilizes efficient intelligent image unwrapping algorithms, enabling seamless and rapid stitching and recording of images when the probe is lowered, supporting real-time storage and on-site playback of fully unwrapped wellbore images and underground videos.

Three-Dimensional High-Precision Sensors

Incorporates high-precision electronic compasses and three-axis sensors, with an accuracy of ±0.1°, capable of measuring various types of vertical, inclined, and horizontal holes.

Automatic Detection, Lightweight and Portable

Employs stepper motors for uniform speed lifting and lowering of the probe, avoiding large errors in depth counting caused by manual lowering, as well as problems such as uneven image stitching, jitter, and mosaic. The device is compact and lightweight, with the winch and cable weighing <10kg for 200 meters, making it extremely convenient for field use and mountain climbing.

Equipped with Electronic Core Library Software

The electronic core library software replaces physical core samples with high-definition borehole image data, addressing issues related to core sampling, transportation, storage, and management.

Specifications

System | Multimedia IPC |

Operation | Touch screen+Buttons |

Display | 8.4-inch TFT LCD display screen |

Storage | 128G SSD |

Collection Speed | ≤60 FPS |

Output Image | ≥2048*2048pix |

Collection Mode | Frame/second puzzle, video, puzzle+video |

Host Size | 350*300*150mm |

Host Weight | 3.5KG |

Lens Type | 360°Panoramic lens |

Probe Clarity | 200 ~ 1000 Mega Pixels |

Probe Diameter | 50mm,63mm(Customizable) |

Probe Lifting Method | Constant speed electric lifting |

Probe Lifting Speed | 0.5 ~ 3.0m/min |

Cable Length | 100 ~ 1500m(Customizable) |

Counting Accuracy | 0.1mm |

3D Sensor | Provide underground 3D attitude display |

Sensor Accuracy | 0.1°Supports horizontal and inclined holes |

Continuous Working Time | 8 hours |

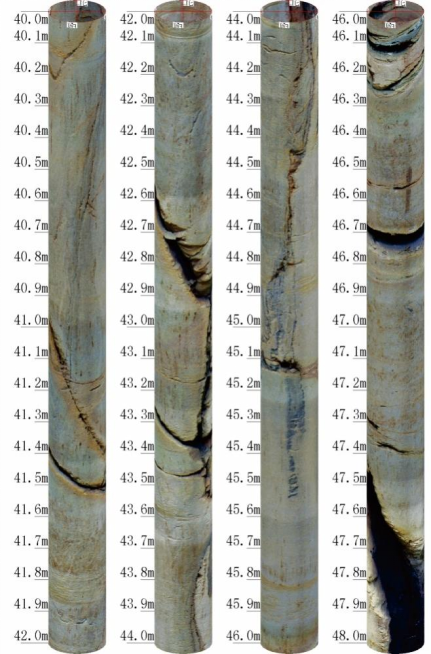

Cases

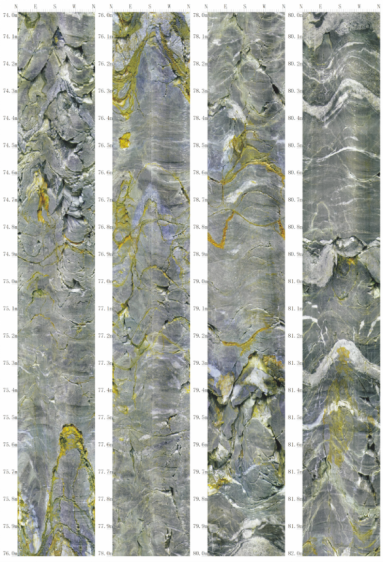

Horizontal Hole Inspection for Hydropower Stations

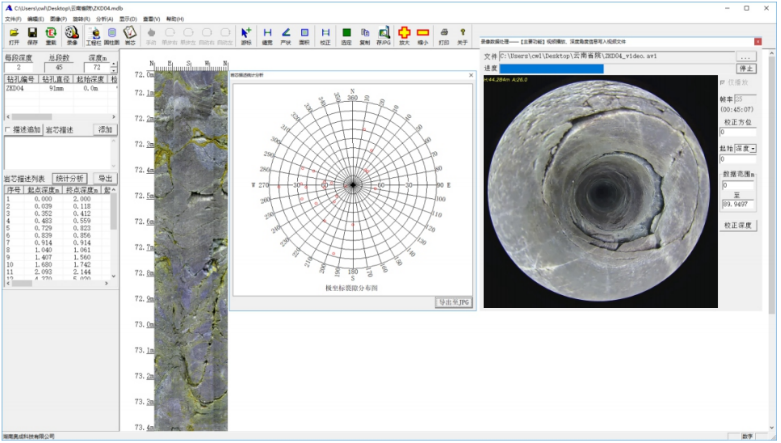

Drilling Puzzle+Video Analysis Interface

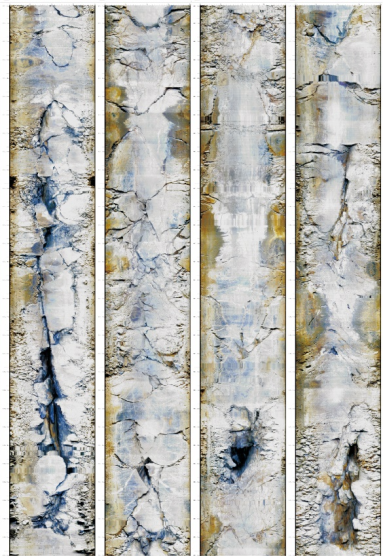

60mm Borehole Measurement Data 76mm Borehole Measurement Data

91mm Borehole Measurement Data

110mm Borehole Measurement Data(3D Bar Chart)