Municipal Road Inspection Case: 3D Array Radar Detection

Quick and accurate detection of road hazards is critical for public safety. A city recently used the LGPR 3D-400AT10 3D Array Radar System to inspect roads, efficiently identifying risks and supporting maintenance plans.

Technical Edge: Efficiency Meets Precision

The system uses a 10-channel array radar (10cm spacing) to collect dense data simultaneously, boosting resolution. Integrated with RTK positioning, it achieves centimeter-level accuracy for defect locations, ensuring precise matching with real sites. Operates at 20 km/h, covering long distances in one go for maximum efficiency.

The system detects various road defects, including:

(1) Standard radar anomaly patterns in normal pavement layers

Due to layered pavement structure and dielectric differences between materials, normal layers show nearly horizontal linear patterns in wave phases/color maps. Signal strength remains consistent within each layer, appearing stable in images.

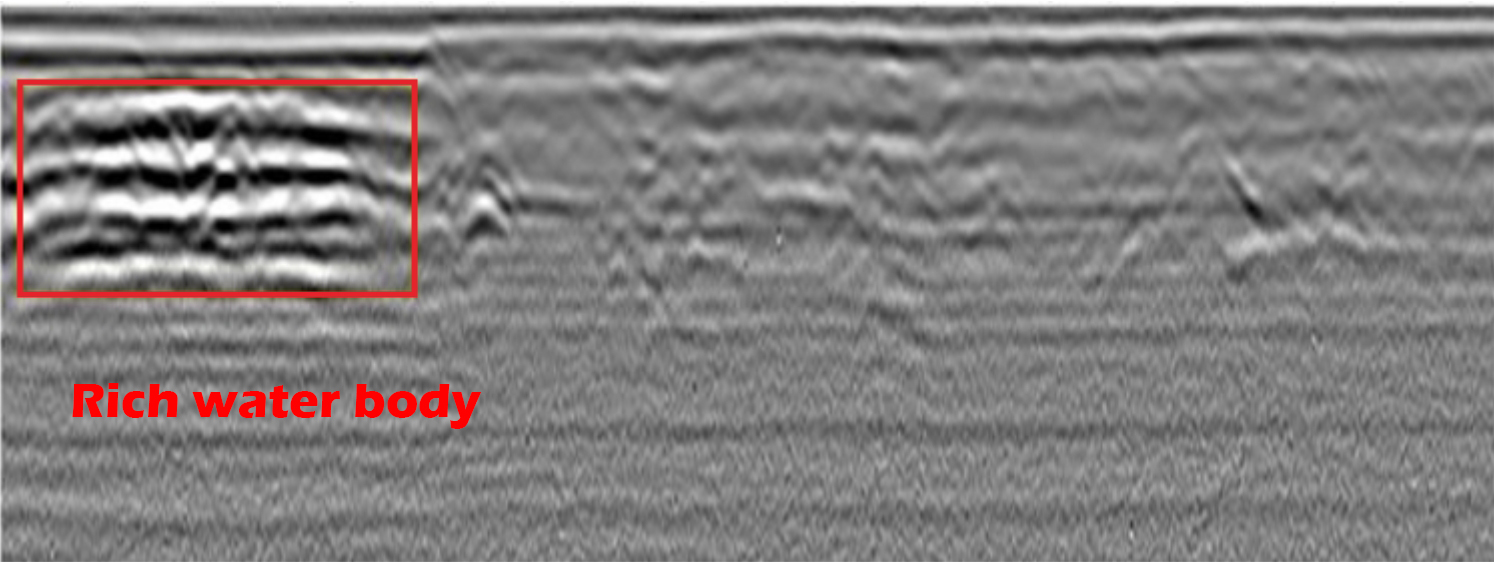

(2) Water-rich areas

Higher relative permittivity than surrounding soil; increases with water content. Radar images show strong top reflection, weakened lower signals, continuous phase alignment, and frequency reduced by water’s filtering effect.

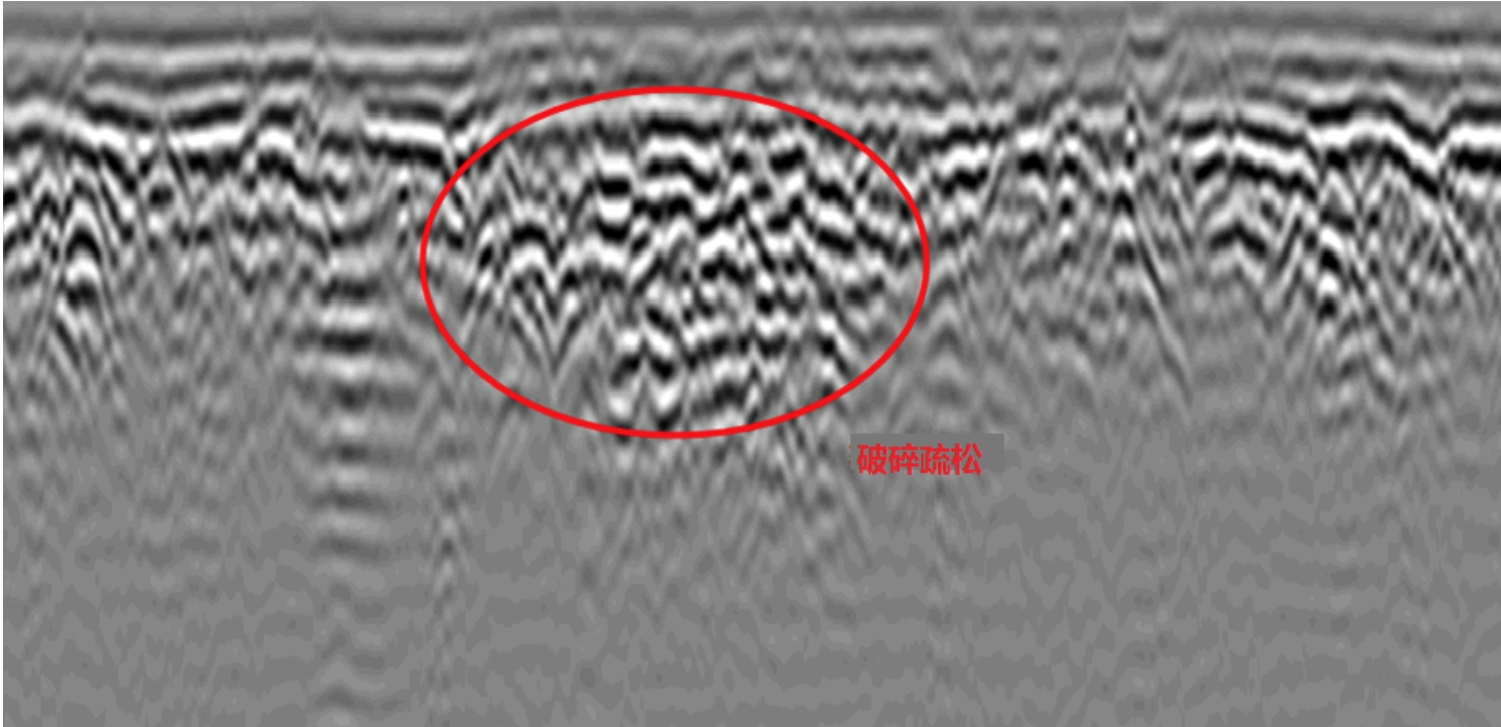

(3) Local compaction issues

Uneven density (e.g., cracks, looseness) creates dielectric differences, reflecting EM waves and producing abnormal radar profiles. Boundary detection: Increased amplitude at uneven interfaces, with phase alignment breaks/bends, longer wavelengths, and distinct signal changes in wave groups.

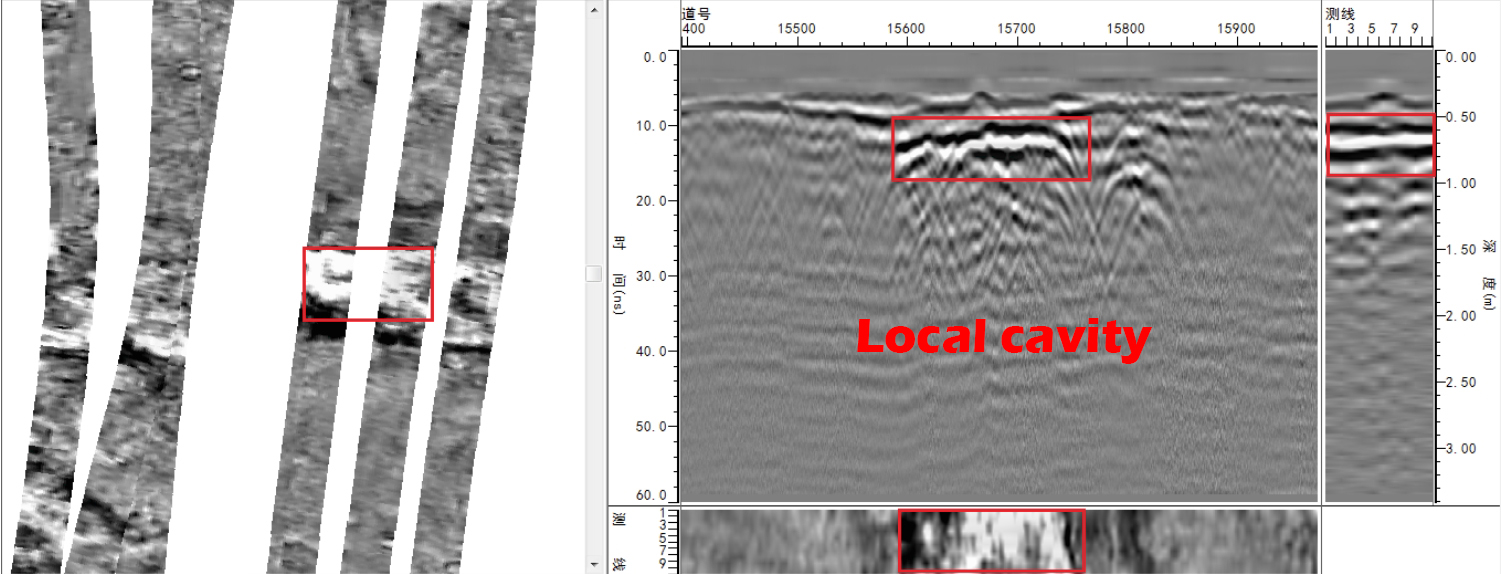

(4) Local voids/cavities

Relative permittivity of 1 (vs. soil’s 6–40) creates sharp dielectric contrasts. Causes clear reflection interfaces and slower wave speeds. Radar images show strong signals, abnormal frequency/amplitude/phase shifts, clear multiple reflections below, and possible diffraction at boundaries.

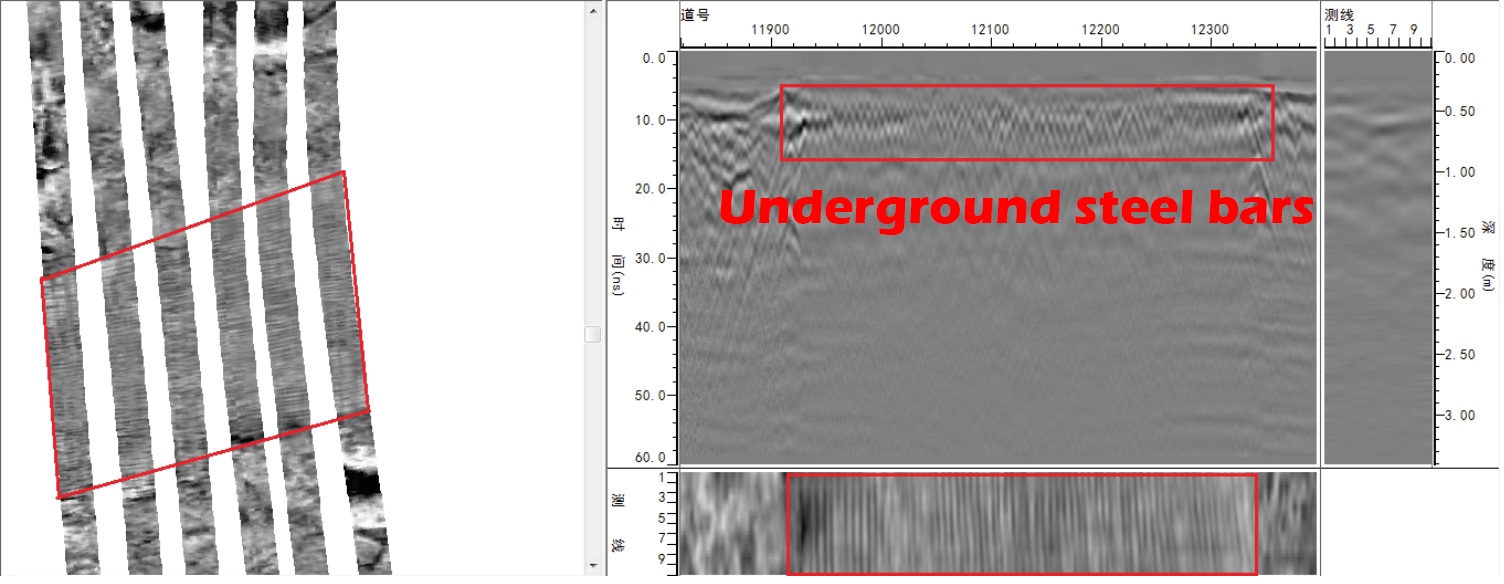

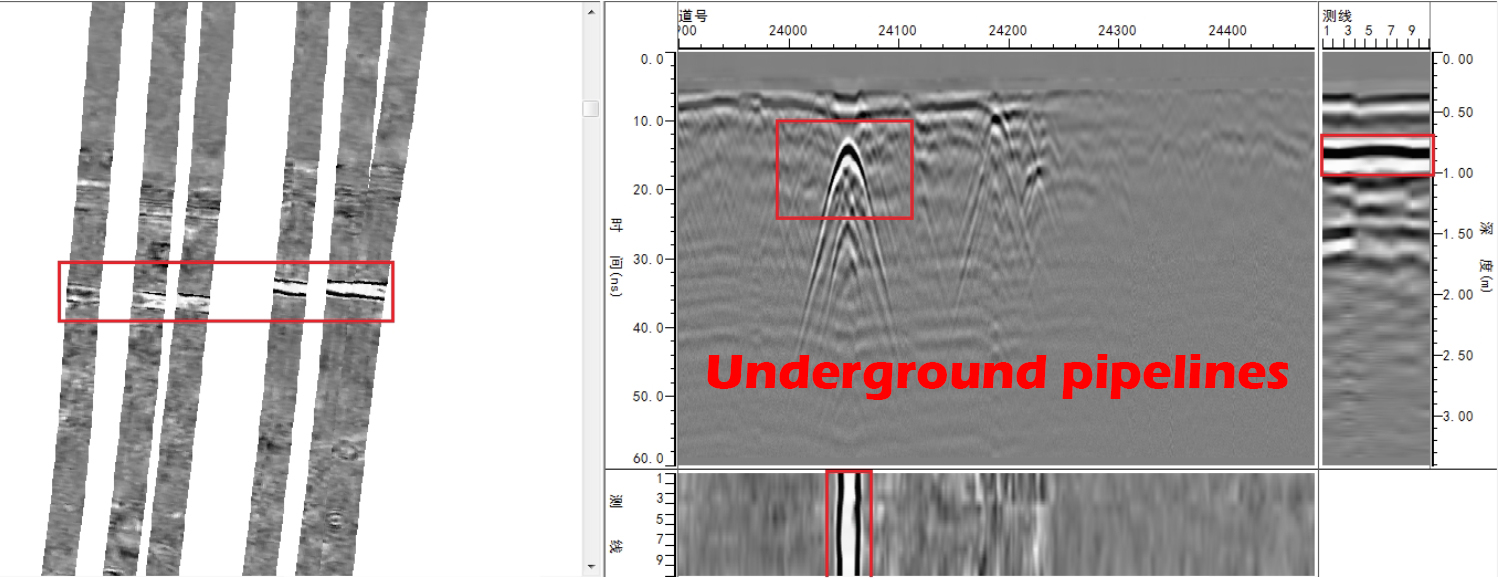

(5) Rebar, pipelines & regular-shaped anomalies

Complex roads have multiple targets. Array GPR imaging filters out these anomalies (regular shapes) to avoid misjudgment.

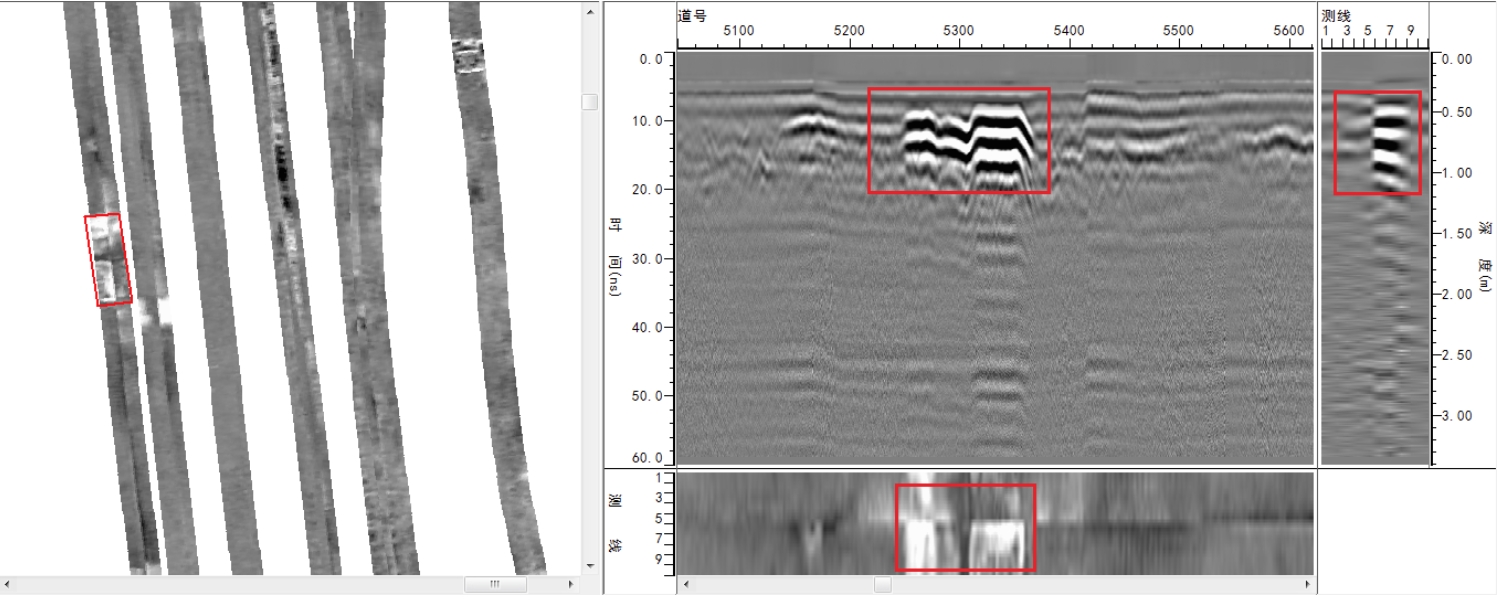

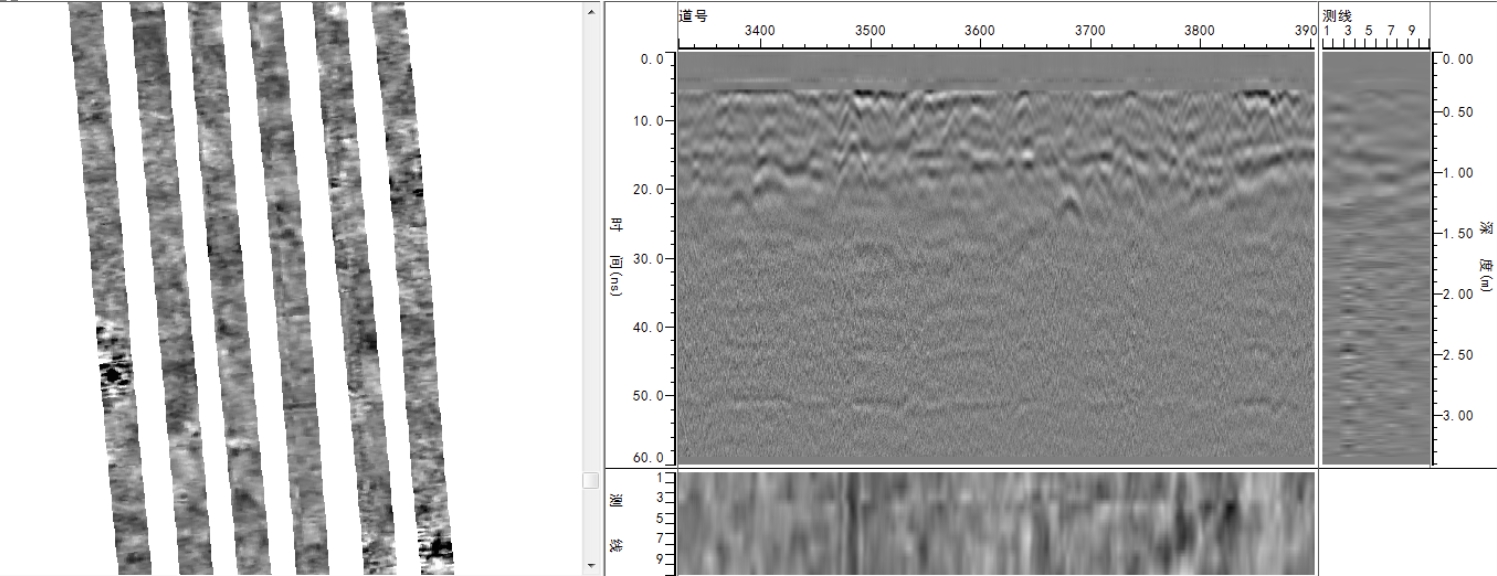

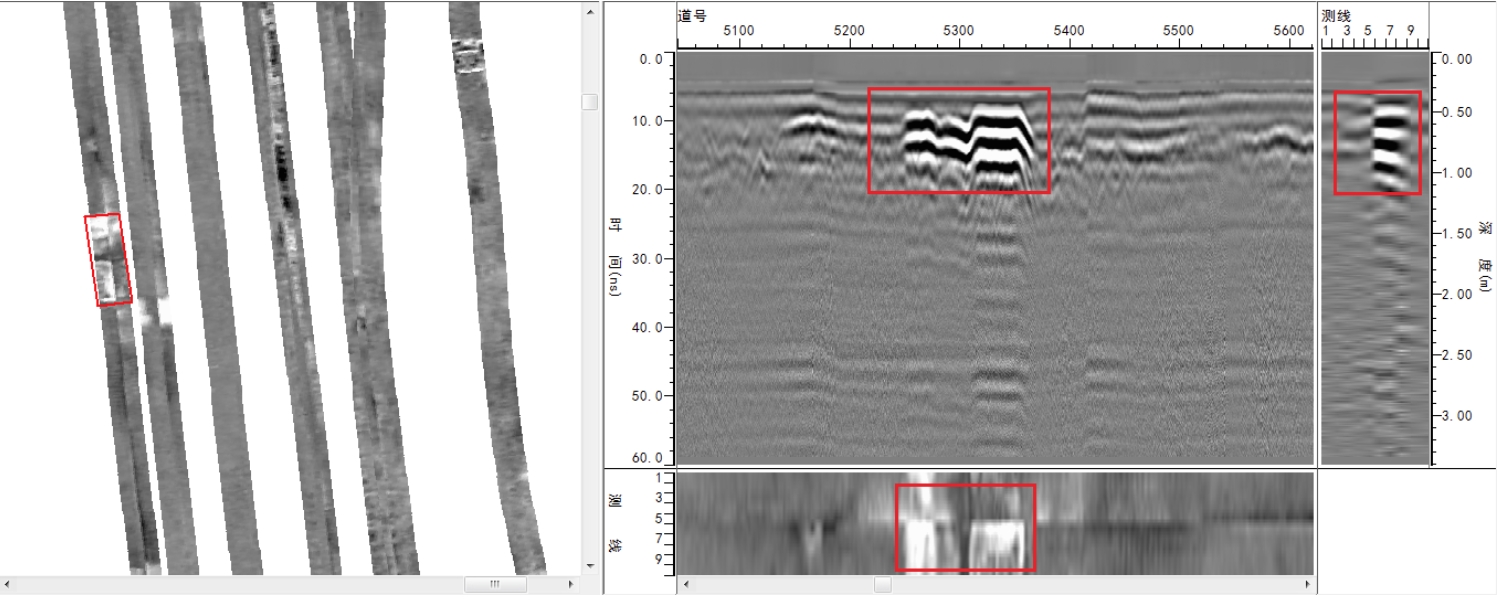

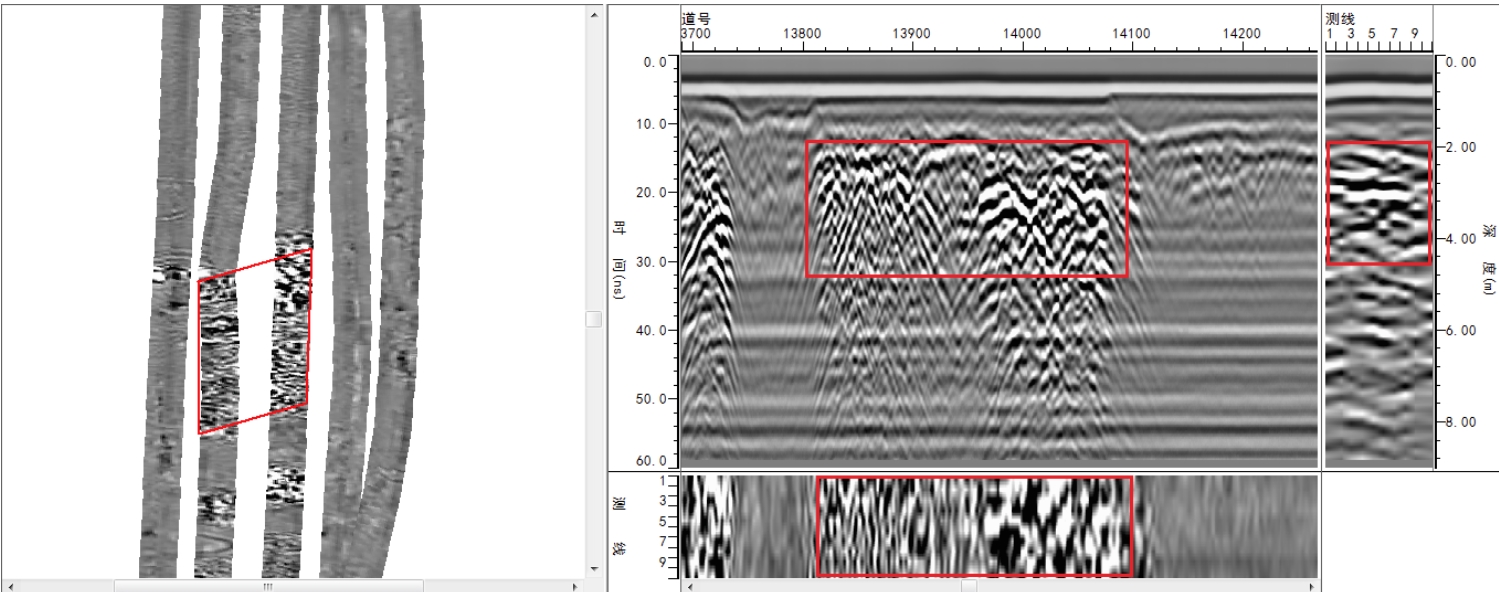

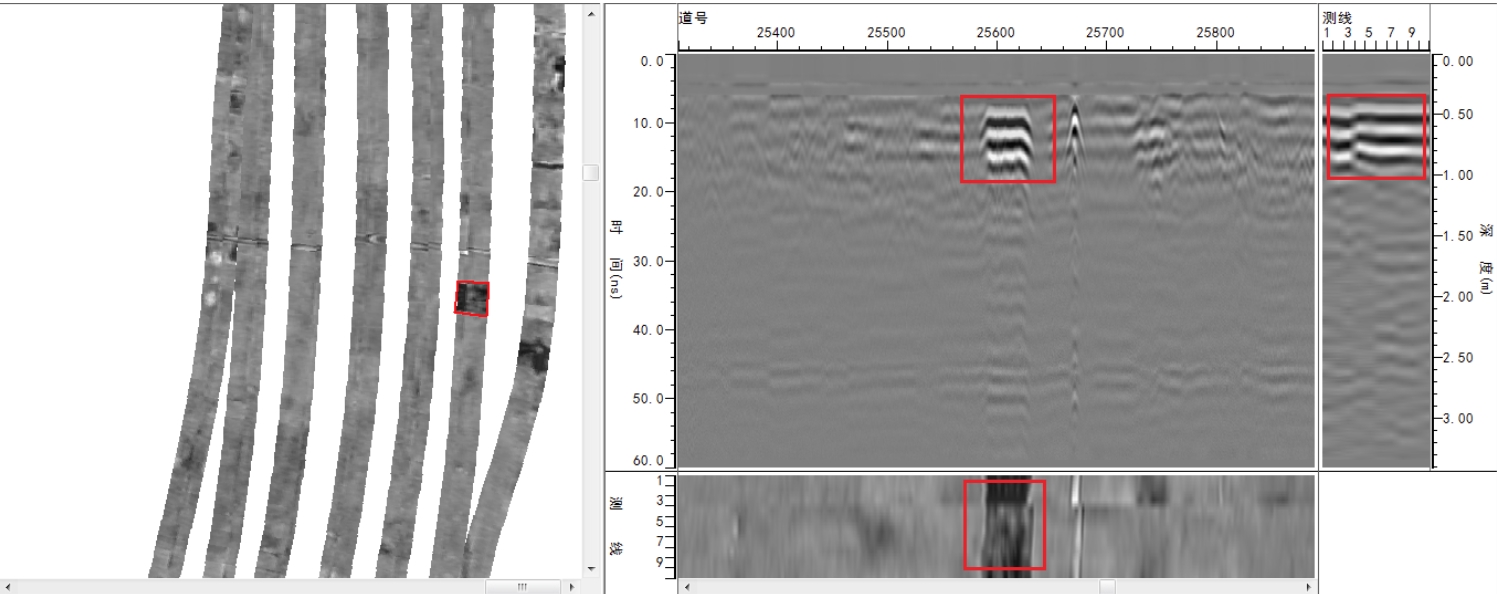

4 Partial Detection Results

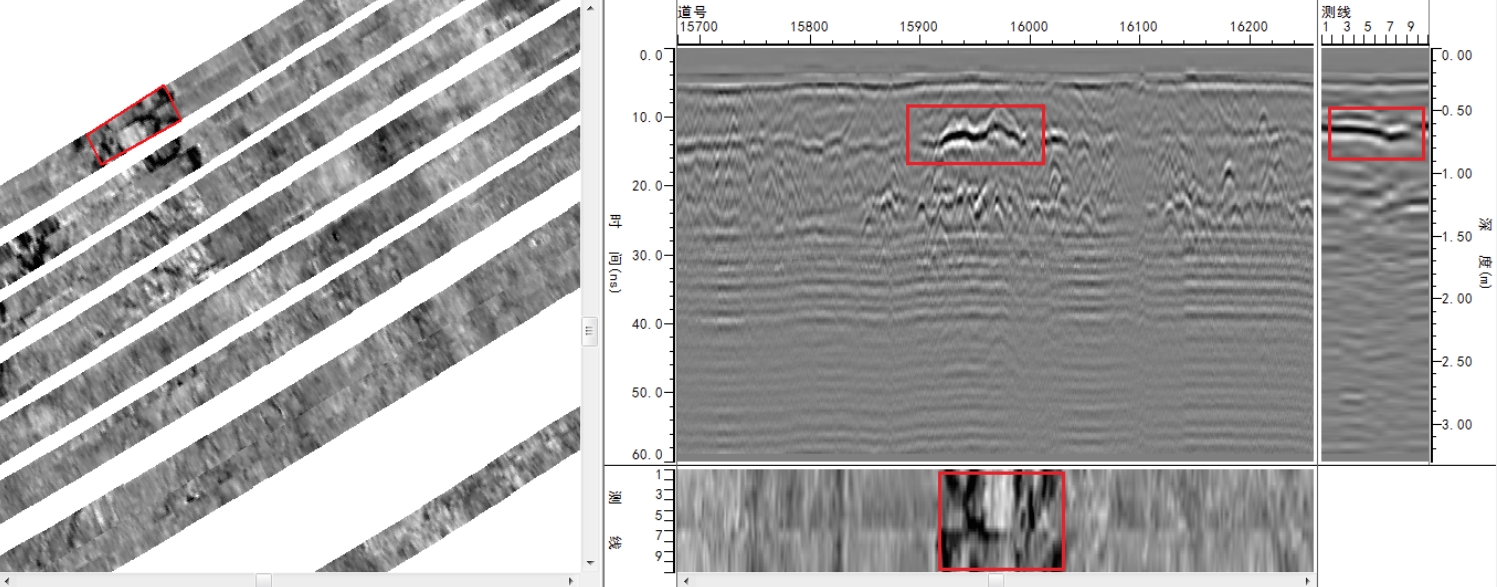

Defect 1 info: Depth ~0.5m; Area ~8m²; Type: Structural layer void; Advice: Regular monitoring.

Defect 2 info: Depth ~0.5m; Area ~7m²; Type: Pipe-surrounding fractures; Advice: Regular monitoring.

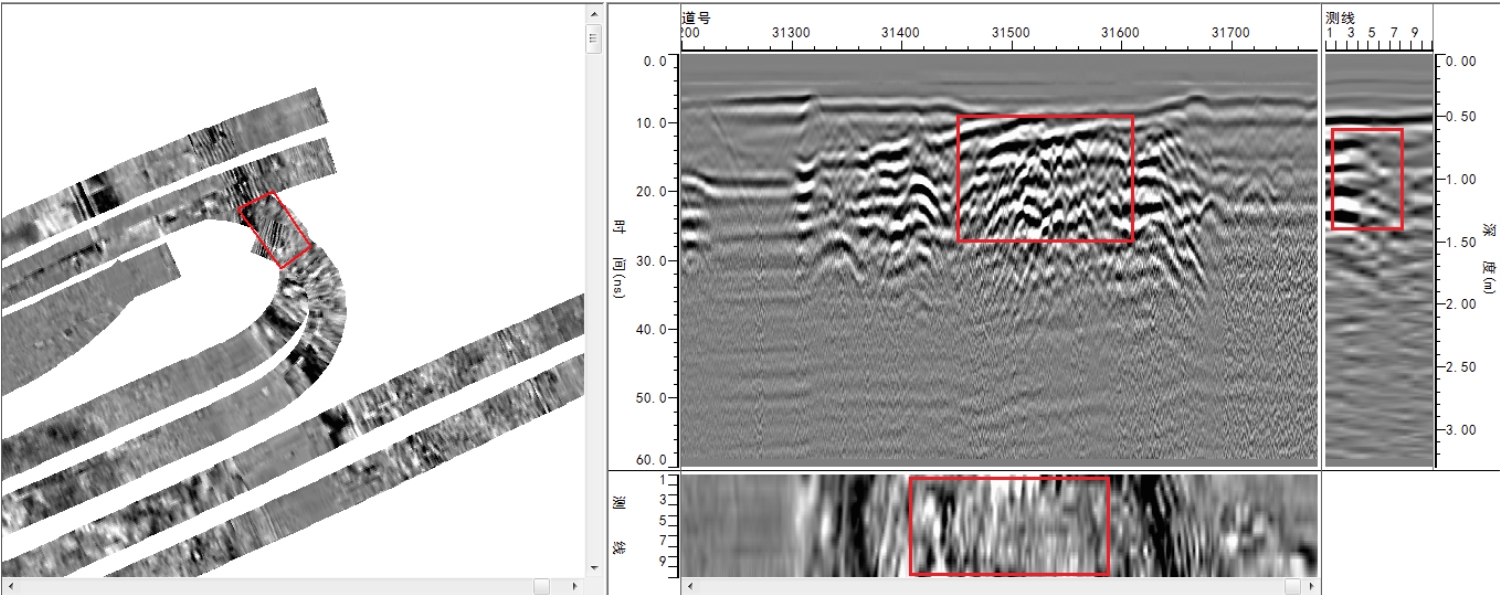

Defect 3 info: Depth ~0.7m; Area ~9m²; Type: Pipe-surrounding void; Advice: Regular monitoring or drill & grout verification.

Defect 4 info: Depth ~0.5m; Area ~30m²; Type: Pipe-surrounding fractures; Advice: Regular monitoring or drill & grout verification.

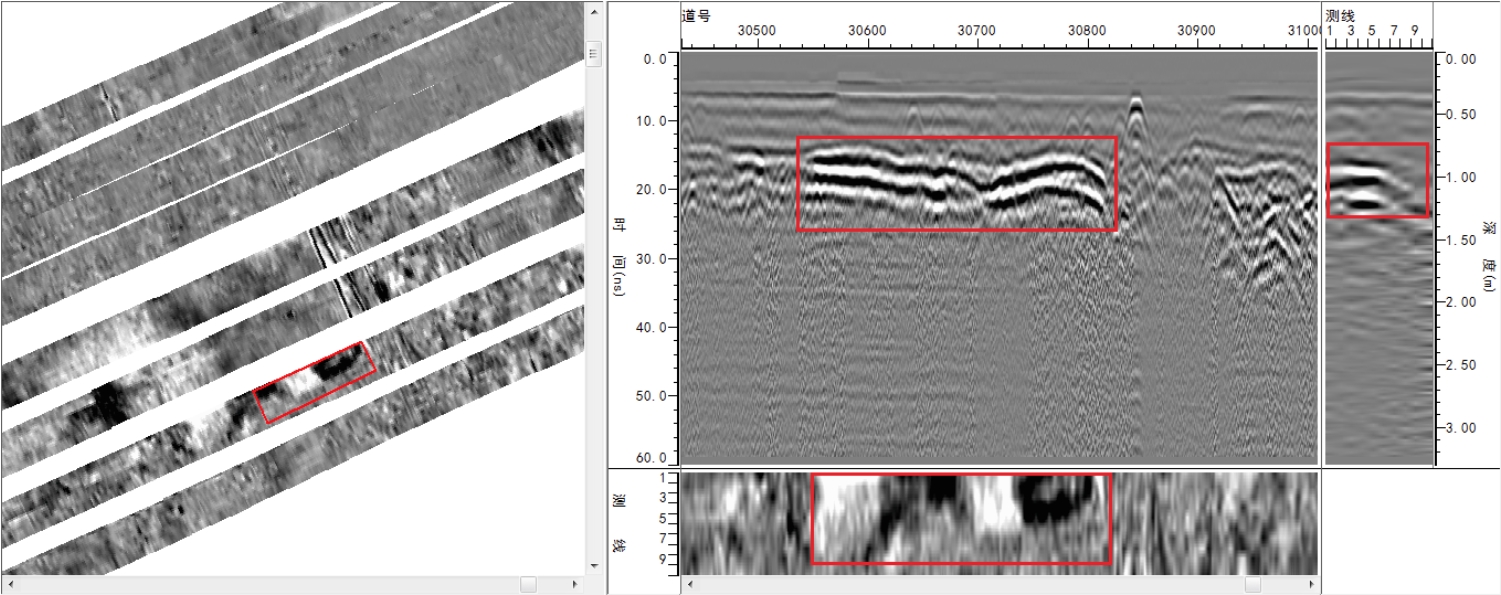

Defect 5 info: Depth ~0.3m; Area ~4m²; Type: Cavity; Advice: Regular monitoring or drill & grout verification.

Defect 6 info: Depth ~0.3m; Area ~6m²; Type: Cavity; Advice: Regular monitoring or drill & grout verification.